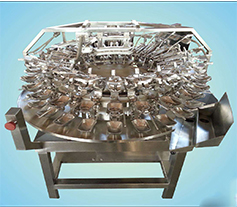

Liquid pasteurization machine

1. All parts of the equipment are made of SUS304/SUS316L stainless steel, and the sleeve gaskets and seals are made of food grade rubber.The connection is made of sanitary pipe fittings, which meets the requirements of the national Ministry of health for food safety testing;

2. Sanitary centrifugal pump circulation;

3. The main heating form of fresh milk pasteurization machine is electric heating (voltage: 220V or 380V);

4. With a jacket of three layers of polyurethane insulation;

5. Cold water and tap water for cooling, cooling water from bottom to top;

6. It has the advantages of good sterilization effect, low noise, adjustable speed, durable, safe and reliable, automatic temperature control and adjustment, simple and convenient operation;

7. Cans of pasteurization machine can be a single tank through the bottom of the sanitary pump cycle, but also can be recycled to each other, the circulation of the milk taste more slippery;

8. Dairy feed can be connected with the sanitary centrifugal pump feeding through the skin tube, can also pass through the material barrel at sanitary centrifugal pump feed;

9. Some parts are placed on stainless steel frame, easy to move, easy maintenance and so on! Milk to milk after pasteurization, sterilization after the completion of both Can be sold, the customer can not only drink, but also can bring home to drink, can also be stored in the refrigerator, the day sales of milk can be produced on the field of yogurt, ice cream, milk shakes and other products;